Volunteer Stories

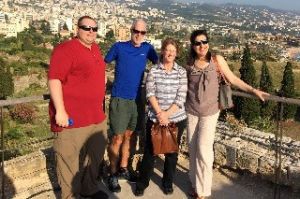

Heidi Lammers, Jerry Heaps and Anthony Vojta

Lebanon

Quality managers on assignment for Farmer-to-Farmer

Quality managers on assignment for Farmer-to-Farmer

Assignment Overview

Assignment Overview

Date: August 2015

Volunteers: Heidi Lammers, Jerry Heaps and Anthony Vojta, all senior quality managers with the Land O'Lakes Quality team

Volunteers Interview:

Welcome back to the United States! What was the structure of your two-week Farmer-to-Farmer assignment?

- Heidi: The first week we facilitated a Hazard Analysis & Critical Control Points (HACCP) training for 20 students enrolled at the American University of Beirut. We had a mix of undergrad and grad students. HACCP, a management system to address food safety, is a third-party course with 11 modules, which lasted the entire week. Though slightly modified, the course is mostly the same training we give at Land O'Lakes twice a year.

- Jerry: The second week, Anthony and I took a one-hour bus ride with the students to two food processing plants, about an hour outside of Beirut, Lebanon. These visits were a lot of fun, and a very useful learning experience for all of us, because we were able to see some of the HACCP course learnings in a practical setting.

The first processing plant you visited was for cheese. What was it like?

- Anthony: I'm what some would call a "cheese-head", so this was my favorite stop. The cheese they make is called halloumi–it's soft, non-cultured, very fresh cheese, made of sheep and goat's milk. Almost like a very bland mozzarella. They coagulate the milk and strain off the whey, then end up boiling the cheese curd back into the whey–a very uncommon process in the United States. There are hundreds of types of cheese in the world, so to see something unique to their culture was very cool. Even though there was a language barrier with the plant owner, we could communicate with the "cheese-making language." It was a unique bonding experience.

- Jerry: In terms of preparation, they typically roll the cheese up in Lebanese bread (similar to a pita) and put it on a griddle to make the cheese melty and stretchy. Then they dress it up with herbs to give it some flavor. The plant has been operating for many years, and they use grandma's unwritten cheese recipe.

Sounds like you met some interesting people!

- Jerry: Yes, the people were very warm and hospitable everywhere we went. Actually, Anthony and I both had our birthdays during the trip–the group surprised us with cake and birthday songs. It was very nice of them to do that for us, and so unexpected.

What a memorable birthday! Let's talk a bit about the tahini paste plant. But first, what exactly is tahini paste?

- Heidi: Tahini paste is made from sesame seeds. The paste is used on hors d'oeuvres and is a main ingredient in hummus.

And what were the highlights of this plant?

- Jerry: In contrast to the cheese plant, the tahini paste plant had many of their procedures and recipes written down, including HACCP critical control points. This is not to say one way of doing things was better than the other; it was just interesting to note the operational contrast. We made some suggestions on how to improve their safety systems. The owner has been using the same processes for 25 years, so it is difficult to just flip a switch and change behavior. This isn't an exclusive challenge to this plant–it's common in the United States, as well.

What surprised you about this trip as it relates to food quality assurance?

- Jerry: [What surprised me was] the wide spectrum of food safety laws worldwide. The U.S. has the FDA and USDA to establish and enforce these policies. It's easy to take these entities for granted. Not all countries have this regulatory infrastructure, so it is an uphill battle to standardize.

- Anthony: To Jerry's point, Lebanon doesn't have a robust food quality regulation, but there appears to be some movement in the this direction. In talking with some of the students, they were hopeful that they will land jobs within the industry as it moves forward in recognizing the value of adopting better quality systems and establishing food safety regulations.

What did you bring back from the experience that will help you in your current job at Land O'Lakes?

- Heidi: The students asked a lot of questions about how to approach getting increased input from management on quality assurance practices. Land O'Lakes is more mature in our commitment to quality, but we hear those same questions at home. It shows that management's commitment to food safety and quality is critical to success–no matter where you are.

- Jerry: In the United States and around the world, people come to these HACCP trainings with various levels of food quality knowledge. I learned the importance of breaking down the lessons into basic terms to ensure people are digesting the information. Anthony is very good at doing this!

- Anthony: Jerry, Heidi and I have diverse quality assurance backgrounds, so as a team we brought a variety of examples to the classroom to help paint the picture for the students. This is important to keep in mind as we facilitate other training programs.

What did you learn about collaborating with the Land O'Lakes International Development team?

- Jerry: We work well with them. They are great at identifying the needs and being specific about our scope of work.

- Heidi: Collaborative initiatives like these help me understand what's going on around the world with food, so it's a unique professional opportunity to collaborate with them. Getting a better worldwide perspective helps me understand how the United States and Land O'Lakes fit into the bigger picture. And I now have a better understanding of how diverse the Farmer-to-Farmer assignments are – I used to think they just focused on dairy and crops, but there is more to it than that. We were there for food safety, and when we were leaving, we met another volunteer coming in to provide financial support to a Lebanese agribusiness. The assignments cover every aspect of doing business in agriculture.

- Anthony: I learned firsthand that as a commercial employee, I can share my expertise as a resource to our International Development projects and make an impact. Just one example, when we first arrived, we toured the plants before the HACCP training. During these tours, we'd made initial suggestions on how to improve some of their processes. Just one week later, the dairy processing plant had already implemented some things we'd talked about. It was rewarding to see that they were so receptive to our suggestions.

The Farmer-to-Farmer (F2F) program sends U.S.-based volunteers on short-term, international assignments to address the needs of agribusinesses and farmers. Land O'Lakes International Development is currently leading an $8 million F2F program in the Middle East and North Africa (MENA) region, working to improve market access for producers, food processors and exporters, along with ensuring that safe foods reach markets. Since 1987, we've fielded more than 1,300 volunteers–including nearly 150 of our own staff and cooperative members–to 27 countries.